Vacuum Hopper Loader

Description

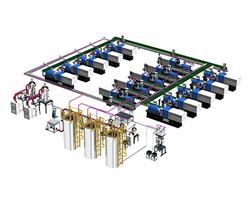

Vacuum hopper loader comprises strong hopper with non-return tangent inlet, robust flap outlet with proximity level switch and optional ‘high fill’ level sensor. Complete with large capacity filters and hinged top cover which includes an air reservoir, and incorporating pulse-jet compressed air filter purge and pipe connection to remote vacuum pump. Requires a supply of clean dry air at 4 Bar.

Features

• 304 stainless steel construction

• Large area cartridge filters

• ‘Pulse-Jet’ filter purge

• Effective filtration to sub-micron

• Integral hopper vent filter

• Flap inspection door

• Hinged cover for filter access

• Integral level control

• Separate 3 phase vacuum pump

• Low maintenance requirement

• Robust construction

• HEPA filter option

Specifications

|

Model

|

Hopper Capacity (L)

|

Conveying Pipe Dia. (inch)

|

Air Suction Pipe Dia. (inch)

|

Control Way of Material Level

|

Dimensions (H × W × D) (mm)

|

Weight (kg)

|

|

THR-3U-S

|

3

|

1.5

|

1.5

|

Magnetic reed switch

|

585 × 260 × 385

|

4.5

|

|

THR-6U-S

|

6

|

1.5

|

1.5

|

Magnetic reed switch

|

555 × 305 × 430

|

8

|

|

THR-12U-S

|

12

|

1.5

|

1.5

|

Magnetic reed switch

|

475 × 335 × 615

|

9

|

|

THR-24U-S

|

24

|

2

|

2

|

Magnetic reed switch

|

825 × 335 × 475

|

14

|

|

THR-36U-S

|

36

|

2

|

2

|

Magnetic reed switch

|

1035 × 335 × 475

|

15

|

|

THR-48U-S

|

48

|

2.5

|

2.5

|

Magnetic reed switch

|

1140 × 400 × 540

|

20

|

|

THR-96U-S

|

96

|

2.5

|

2.5

|

Magnetic reed switch

|

1385 × 476 × 625

|

24

|

|

THR-3U-ES

|

3

|

1.5

|

1.5

|

Interactive photo sensor switch

|

740 × 260 × 385

|

7

|

|

THR-6U-ES

|

6

|

1.5

|

1.5

|

Interactive photo sensor switch

|

740 × 295 × 430

|

10

|

|

THR-12U-ES

|

12

|

1.5

|

1.5

|

Interactive photo sensor switch

|

840 × 340 × 475

|

14

|

|

THR-24U-ES

|

24

|

2

|

2

|

Interactive photo sensor switch

|

1260 × 370 × 475

|

16

|

Supplies vacuum excavators, street sweepers, vacuum loaders, sewer cleaners and camera systems in USA.

Manufacturer of control equipment for automatic leak testing machines and leak test systems for assembly lines or laboratories.

Robotic components including grippers, gantry loaders, indexers, and automatic tool changing systems.

Designs and manufactures equipment for plastic industry. Products include vacuum loaders, plastic granulators, railcar unloaders, and temperature control unit.

Portuguese manufacturer of plastic granulators and auxiliary machinery including mixers, belt conveyors and material handling equipment.

Full line supplier of auxiliary plastic equipment, granulators, hopper dryers, chillers, vacuum blowers, silos barrels, screw tips and cyclone collection bins.

Manufacturer of rotary vane vacuum pumps in Italy. Applications include vacuum packaging, chemical and processing industries as well as heat treatment.

Germany. Design and manufacture of industrial vacuum units, truck mounted vacuum loaders, and stationary vacuum cleaning, vacuum conveying and dust extraction units. Vacuum cleaners and stationary separators for the textile and nonwovens industries. Multi-lingual site.

Manufacturer of Industrial venturi style vacuum pumps, cups, and accessories for material handling. Specializing in custom solutions for difficult applications.

Describes products, including valves, jet loaders, belt and screw conveyors, filters, silo measurement devices, flow bows, and hoppers.

Biography.

Provides the UK plastics industry with automation machinery and ancillaries including gravimetric blenders, polymer dryers, belt conveyors,material handling systems, robots, hopper loaders, shredders,granulators and other associated equipment.

English

English Русский

Русский Español

Español العربية

العربية