Product List

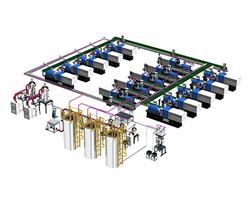

Central Feeding System

- Central Control Station

Central control station is the controller of the entire central feeding system. It can be programmed based on actual demands to monitor the feeding system, remove dust, feed materials, send alarms, etc. This central control system has a wide range of reliable capabilities that can be easily expanded, and it can support up to 36 machines running simultaneously....

Tag: PLC Control Unit | PLC Controllers | Programmable Logic Controllers | Programmable Controllers

- Hopper For Loader

THR-US series hopper loaders are necessary equipment for the central feeding system. We offer two types of hopper loaders to control the material level: Vacuum hopper (U): control the material level with magnetic reed switch, mounts directly on a dryer. Photo sensor hopper (U-E): control the material level through interactive photo sensor switch, can be installed directly on the molding machine....

Tag: Self-contained Hopper Loaders | Motorless Cast Alloy Vacuum Hopper Loaders | Motorless Vacuum Hopper Loaders | Single Phase Hopper Loaders

- Central Filter Unit

The central filter unit mainly consists of dust collector, blower and stainless steel tube. It can filter the dust and small impurities in the material based on specific demands of customers with reduced labor costs....

Tag: Dust Filter Unit, Air Filter Unit | Central Filter Equipment | Dust Disposal Unit | Portable Filtration Unit

- Central Vacuum Generator

This central vacuum generator mainly consists of control box, blower and tube. It helps to create a vacuum environment for raw material conveying. Our vacuum generation unit is applied to provide vacuum environment for material conveying, and is usually used together with central filter unit, hopper loader, etc....

Tag: Central Vacuum Stations | Central Vacuum Generating System | Vacuum Generation Device | Vacuum Generating Machines

- Central Raw Material Distribution Station

TMDS series central material distribution station plays its role in distributing raw materials to each storage hopper. This central distribution station is designed with quick couplings for easy assembly and disassembly. It’s made of stainless steel, preventing the raw materials from being contaminated. Five dimensions are available with this central distribution station....

Tag: Material Distribution Equipment | Material Distribution System | Central Raw Material Distribution Station

- Metal Separator

TMS series metal separator is highly efficient and accurate in separating precious metal contained in raw materials, such as stainless steel, iron, copper, aluminum, tin, etc. When the metal impurities go through the electronic detector, the detector will send signals, and materials with metal impurities will be separated through the pneumatic valve....

Tag: Metal Detector | Non-ferrous Metal Separators | Pneumatic Metal Separators | Magnetic Separators

- Centralized Automation System

Our centralized automation system is designed to remotely control and detect production data by connecting to Ethernet and Internet, so as to realize centralized control over the entire factory in the office or control center....

Tag: Automatic Control Systems | Automation Control Systems | Centralized Management System | Automatic Central Control Systems

Our central feeding system offers a complete solution for plastic raw materials through vacuum conveying and centralized automation control realized by PLC human machine interface.

LANTYTK® Machine offers equipment that involves storing, dehumidifying, drying, feeding of plastic raw materials, temperature control of molds, cooling of forming machines, handling of materials by manipulators, recycling of waste materials, etc.

Advantages

1. Life-long free maintenance service is offered for our central feeding system.

2. Noise of our automatic feeding system is lower than 80dB, a level that leads in the global market, providing a relatively quiet working environment for our staff.

3. Automatic cleaning function helps to keep the pipe clean.

4. Hoppers of different capacities are available based on user’s specific needs.

5. 304 stainless steel improves appearance attractiveness as well as durability of our material feeding system.

6. Corrugated hose is used where the hopper and pipe connects, ensuring the tightness of the connection.

7. High degree of automation with low running costs and labor costs.

8. All electrical components used by our central feeding system are supplied by Siemens, Omron, Schneider and other brands, ensuring the stable performance of these components and the system.

9. PLC control and user-friendly touch screen allows improved convenience in operation.

10. Reduced inventory of spare parts and decreased requirements on maintenance help save costs.

Note

Please choose the right pipe based on your specific needs and required materials.

English

English Русский

Русский Español

Español العربية

العربية