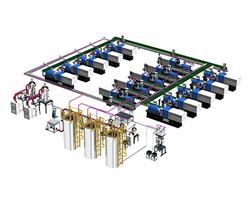

Central Controller

Features

• Central In-feed Controller: PLC × 10.4

• LCD touch screen of this central controller to control work status

1. Operation state: major material feeding machine ON/OFF indicates failure, material type, the lack and full state of material etc.

2. Display and adjust material suction time.

3. Display and adjust air pumping time.

• Reliable, user-friendly European-spec safety plug.

• CE-approved, highly functional, expandable; supports up to 40 material conveyors for molders.

• Warning of insufficient air compression, vacuum material-barrel cleaning, automatic dust reverse-washing, foolproof auto main-unit switching and material change.

Options

▲ Communication functions for remote monitoring and control.

▲ Fingerprint to start the power, may authorize 5, 10 …50 people to avoid the inconveniences of key management including storage, loss, replication and inappropriate transfer.

▲ With a fingerprint recognition system to increase the record function, which can record who and when of the machine switching, the hours of use or the change of parameters.

Technical Parameter

|

Model

|

Installation

|

Material Selection Stations

|

Voltage

|

Dimensions (mm)

|

Weight (kg)

|

|

TCCS-100-W

|

Wall-mounted

|

12 stations

|

1Φ/230V

|

430 × 370 × 800

|

40

|

|

TCCS-200-W

|

Wall-mounted

|

24 stations (12 × 2)

|

1Φ/230V

|

430 × 370 × 800

|

42

|

|

TCCS-300-W

|

Wall-mounted

|

36 stations (12 × 3)

|

1Φ/230V

|

430 × 370 × 800

|

45

|

|

TCCS-100-G

|

Floor standing

|

12 stations

|

1Φ/230V

|

1230 × 600 × 700

|

75

|

|

TCCS-200-G

|

Floor standing

|

24 stations (12 × 2)

|

1Φ/230V

|

1230 × 600 × 700

|

77

|

|

TCCS-300-G

|

Floor standing

|

36 stations (12 × 3)

|

1Φ/230V

|

1230 × 600 × 700

|

80

|

A manufacture of temperature sensors for process control applications includes thermocouples, RTDs, digital indicators, transmitter and termination heads.

Manufacture temperature controllers, indicators, sensors, process scanners, and humidity indicators.

A manufacturer of multi loop and single loop temperature controllers, process controllers, indicators, control systems and level meters as well as temperature sensors, humidity sensors, level sensors, pressure transducers and recorders.

Manufacturer of injection molding temperature controllers.

Tooling manufactured to very close tolerances on state of the art CNC machine tools, in a temperature controlled environment.

Manufactures products for the molding and mold-making industries, offering everything from standard ejector pins to complex runnerless mold systems with precision temperature controllers.

Provides electrical and control system engineering consulting and integration services throughout the Northwestern United States.

Manufacturers of a range of electronic industrial controls including counters, timers, tachometers, proximity sensors, power supplies and level controllers.

Offering Fanuc and GE Fanuc CNC parts and repair service to America. Includes drive units (AC Alpha), monitor replacements, control pcb, power supply, servo motor encoders. Site useful machine tool information.

Manufacturer of monitor replacement equivalents for the CNC industry. Including Fanuc, GE, Siemens, Mazak, Mitsubishi, Matsushita. Company based in UK, ships immediately worldwide.

Application monitors print jobs and alerts you when you've been printing too much. Limits on print volume are controlled by the user.

A free startup manager and monitoring program, it can scan all Windows Startups on your computer, and monitor all new startup items, helps you control, manage and optimize Windows Startup configuration.

English

English Русский

Русский Español

Español العربية

العربية